Jiangyin Tianyang Drying Technology Co., Ltd.(Jiangyin Drying Machinery Plant)

--Committed to the development of drying technology, the development of new drying equipment, the research, design and manufacture of...

Uses: it can be used in drying, cooling and humidifying powdery materials in chemical, pharmaceutical, food, beverage, seed, slag, and other industries.

Characteristics

□ Vibration source adopts vibration motor. Stable operation, convenient maintenance, low noise, and long service life.

□ Uniform fluid-bed, without the phenomenon of gap and blowing out. The uniform dry and cool products can be got.

□ Thickness of feed layer, movement speed and total amplitude change can realize stepless regulation.

□ Less damage to the surface of material. It can be used for drying material that is easy to broken. If the granule of material is unregulated, but the work effect is not be affected.

□ The closed structure can prevent the cross infection between material and air.

□ High mechanical efficiency and heat efficiency, good energy-saving effect.

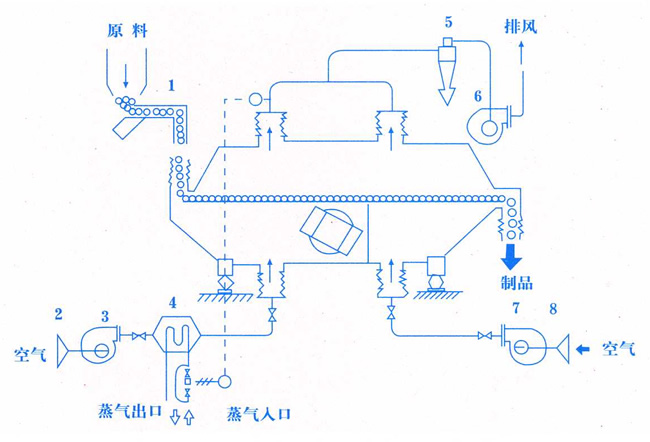

ZLVibrating fluidized bed dryer system chart

1 Vibratory feeding 2 Air filter 3 Blower 4 Heater 5Dust collector 6Induced draft fan 7 Blower 8Air filter

Size chart of reactor for use in sodium diacetate

| A | B | C | D | E | F | Weight (Kg) |

| 3000 | 300 | 1350 | 950 | 430 | 1700 | 1240 |

| 600 | 1650 | 950 | 430 | 1700 | 1400 | |

| 900 | 1950 | 950 | 600 | 1850 | 1630 | |

| 1200 | 2250 | 950 | 800 | 2050 | 2030 | |

| 1500 | 2650 | 950 | 1000 | 2250 | 2430 | |

| 4500 | 300 | 1350 | 950 | 430 | 1700 | 1570 |

| 600 | 1650 | 950 | 430 | 1700 | 1860 | |

| 900 | 2000 | 950 | 600 | 1850 | 2430 | |

| 1200 | 2300 | 950 | 800 | 2050 | 3030 | |

| 1500 | 2600 | 950 | 1000 | 2250 | 3680 | |

| 6000 | 300 | 1350 | 950 | 430 | 1700 | 1960 |

| 600 | 1700 | 950 | 430 | 1700 | 2410 | |

| 900 | 2000 | 850 | 600 | 1850 | 3160 | |

| 1200 | 2400 | 950 | 800 | 2050 | 3580 | |

| 1500 | 2700 | 950 | 1000 | 2250 | 4230 | |

| 7500 | 600 | 1700 | 950 | 600 | 1700 | 3900 |

| 900 | 2100 | 950 | 430 | 1850 | 4140 | |

| 1200 | 2500 | 1150 | 800 | 2040 | 5190 | |

| 1500 | 2850 | 1150 | 1000 | 2450 | 5940 |

Uses of reactor for use in sodium diacetate

| Number | Material name | Physical condition | Moisture before drying | Moisture after drying | Handling capacity each hour (kg) |

| 1 | Citric acid | Pigment | 2.5% | 0.5% | 300-1500 |

| 2 | Fine shell powder | Powder | 9.1% | about 0 | 450-1500 |

| 3 | Coarse shell powder | Mixed particle | 11% | about 0 | 500-2000 |

| 4 | Steel frit | Mixed particle | 6.45% | about 0 | 500-2000 |

| 5 | Medical stone | Particle | 5% | 0.02% | 600-2500 |

| 6 | Hydroxyethyl fiber | Flocculent | 67.5% | 3.5% | 250-1000 |

| 7 | Quartz sand | Fine powder | 5% | about 0 | 1000-3000 |

| 8 | Phthalimide | Particle | 33.3% | 0.1% | 190-500 |

| 9 | Detergent | Powder | 10% | 1.75% | 300-900 |

| 10 | Copper powder | Powder | 8.5% | 0.5% | 500-1500 |

| 11 | Boric acid | Fine powder | 10% | 0.1% | 500-1000 |

| 12 | Borax | Particle | 6% | 0.1% | 500-1000 |

Ordering instruction

Please offer name, characteristics (including water content before and after drying, true specific gravity, particle size, viscosity, heat resistance, etc) and drying output of materials.

Add: Yunting Town, Jiangyin City, Jiangsu, China.

Tel: +86-510-86151526

Fax: +86-510-86010526

Contact: Zhang Yong mobiles: +86-13901522956

E-mail: zhpxyy@126.com